Electrical Inspections

An essential part of preventive maintenance

As Electrical Contractors, we provide electrical inspections using thermal imaging, often referred to as thermographic inspections, to assess the condition of electrical systems and equipment. Thermal imaging allows professionals to detect temperature variations and hotspots in electrical components, which can be indicative of potential issues, such as loose connections, overloaded circuits, or failing components.

Here's how electrical inspections by electrical contractors using thermal imaging work:

-

Equipment and Tools:

Electrical Contractors use thermal imaging cameras or infrared (IR) cameras for these inspections. These cameras capture the temperature distribution across the surfaces of electrical equipment and display it as a thermal image or thermogram.

-

Preparation:

Before conducting the inspection, we ensure that the electrical system is energized and under a typical load. This helps to identify abnormalities that may not be evident under no-load conditions.

-

Scanning:

Thermal imaging cameras scan the electrical equipment, including circuit breakers, distribution panels, switchgear, wires, and connections. The camera records the temperature of these components, highlighting variations.

-

Analysis:

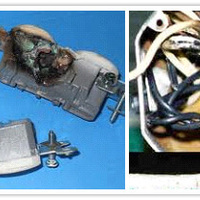

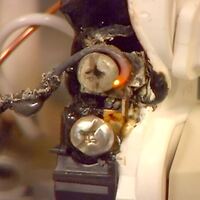

The thermographic images are analyzed for hotspots or temperature anomalies. These hotspots can indicate issues such as loose connections, overloading, imbalanced loads, or failing components.

-

Report:

Based on the thermal imaging data, we would prepare a report that includes images of the hotspots and their locations. The report may also provide recommendations for corrective actions and necessary repairs.

-

Maintenance and Repairs:

Once issues are identified, we can work with the client to plan and execute maintenance or repairs to address the problems and prevent potential electrical failures.

The benefits of thermal imaging inspections in electrical systems include:

-

Early Problem Detection:

Hotspots are often early indicators of electrical issues, allowing for proactive maintenance and preventing costly failures.

-

Enhanced Safety:

Identifying potential problems before they escalate can improve electrical system safety, reducing the risk of fires and accidents.

-

Improved Efficiency:

Resolving issues like loose connections or imbalanced loads can improve the efficiency of the electrical system, reducing energy consumption and operational costs.

-

Compliance:

Regular thermal imaging inspections can help meet regulatory requirements and industry standards for electrical system maintenance and safety.

Electrical inspections using thermal imaging are an essential part of preventive maintenance for commercial and industrial electrical systems. They should be performed regularly to ensure the safety, reliability, and efficiency of the electrical infrastructure.

Why Call Us ?

Whether you are undertaking a major renovation, a new build or just need a new fixture installed, we are able to provide you with the best in service.

- We want to speak with you - we don't believe in voice mail.

- We love to help you get results on any job big or small.

- We are certified, bonded and licensed.

- We are dedicated to ensuring we use the best practices according to Skilled Trades BC, we use good quality materials, and don’t take shortcuts or hide things that other trades will find down the road.